On July 1, the State Council issued the "Internet Plus" Action Guidance, which clearly proposed to promote intelligent manufacturing, mass personalized customization, networked collaborative manufacturing and service-oriented manufacturing in key areas, and develop a new collaborative manufacturing model based on the Internet. Industrial Internet is the key foundation for realizing intelligent valve manufacturing and the core element of Internet+system.

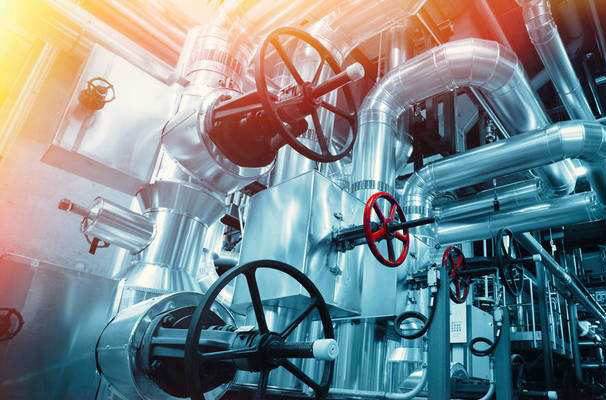

Industrial Internet is a "end managed cloud" architecture composed of "intelligent machine"+"network"+"industrial cloud platform", which can realize the comprehensive connection and interaction between machines, machines and people, and between people. This interconnection is not simply the transmission of data information flow, but integrates technologies such as intelligent hardware, big data, machine learning, and knowledge discovery, extending the intelligent control of a single machine and some key links to the entire process of valve production, promoting machine self-organization, self decision-making, and adaptive production without human intervention, laying the foundation for the implementation of intelligent manufacturing of valves.

Industrial Internet makes production definable. Traditional valve production heavily relies on fixed molds and fixed production lines. Raw materials, machines, equipment groups, and other production facilities are configured according to maximum production demand, which can easily cause great waste during idle production periods and cannot be flexibly adjusted during the production process. Under the condition of industrial Internet, the intelligent control of machines and open source hardware is completed by software, and the intelligent control chain is extended to all aspects of production through interconnection, promoting the transformation of production process to an intelligent direction that can be defined, managed and executed by software. For example, software can calculate production demand and flexibly adjust raw material inventory; Machine functions can be upgraded to increase its production capacity and applicability; It can achieve intelligent device allocation, configure production tasks and workloads as needed, and ultimately achieve intelligent production.

Industrial Internet makes production dynamics adjustable. The production process collaboration of traditional valve enterprises can only achieve small-scale collaboration among various departments and workshops within the enterprise. The industrial Internet has broken through the time-space boundary, integrated the supply chain, customer relations, manufacturing execution, enterprise resources and other systems, built an information sharing platform for enterprises and partners in the entire supply chain, expanded the production process collaboration to the whole supply chain and even across the supply chain, realized the network configuration of advantageous resources and advantageous enterprises in the whole production process, and realized the real socialized large-scale collaborative production.

At present, the construction of China's industrial Internet has begun. We should focus on breaking through a number of key core technologies, and speed up the key technologies of the perception layer, network layer and application layer of the industrial Internet in combination with the implementation of major scientific and technological projects. The perception layer is the terminal link of industrial Internet to identify objects and collect information, which includes not only the intelligent terminal information collection technology required for various production such as machines, equipment groups and production lines, but also the perception terminal information collection technology such as RFID tags, sensors, cameras, two-dimensional barcodes, telemetry and remote sensing. The network layer is the central link of information transmission and processing in the industrial Internet. The network layer includes the integration technology of industrial heterogeneous networks, the IQ technology of industrial equipment and products, the access and utilization technology of industrial big data, and the industrial Internet architecture